Today innovation is considered a basic force driving development in advanced countries. In a sector as competitive as ceramics, it has become a key factor for companies. But this means a type of innovation that goes beyond incorporating new technology into the manufacturing process for a product; it is a question of foreseeing market needs to generate new products or product features at the lowest possible cost.

Bathco bases its success partly on its capacity to generate new products and anticipate the needs of the market. In doing so, it works with institutions dedicated to research and innovation like the Component Technology Centre of Cantabria (CTC). We talk to Beatriz Sancristóbal, the director of new projects at the CTC, who explains the details of the new material they have developed for the washbasin manufacturer.

Bathco bases its success partly on its capacity to generate new products and anticipate the needs of the market. In doing so, it works with institutions dedicated to research and innovation like the Component Technology Centre of Cantabria (CTC). We talk to Beatriz Sancristóbal, the director of new projects at the CTC, who explains the details of the new material they have developed for the washbasin manufacturer.

What does the collaboration between Bathco and the CTC consist of?

The Component Technology Centre collaborated with Bathco on an R&D project to develop cement sinks with better properties thanks to the use of nanomaterials.

The collaboration, which started just over two years ago, is a success story that clearly exemplifies the benefits that can come from a partnership between an innovative company and Cantabria’s only technology centre, because the result was a product with the properties required to cover a market niche.

How did the CTC approach the project Bathco presented to you?

We approached the project with great enthusiasm. The bathroom sector is a new one for us, and so it is full of opportunities to be explored. The Advanced and Nanomaterials area of the CTC faced the challenge of improving the properties of washbasins from the starting point of a conventional material like cement.

What was the research work like?

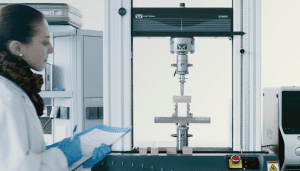

We were familiar with the material and also with the problems associated with these types of products at the moment, such as the effects of moisture. The CTC team working on the project selected the ingredients of the new formula one by one, to ensure that the end product would satisfactorily meet all the requirements proposed by Bathco. Following this selection, there was an experimental phase in our laboratories. This stage consisted of combining the ingredients in different proportions until the properties identified by Bathco were achieved.

We were familiar with the material and also with the problems associated with these types of products at the moment, such as the effects of moisture. The CTC team working on the project selected the ingredients of the new formula one by one, to ensure that the end product would satisfactorily meet all the requirements proposed by Bathco. Following this selection, there was an experimental phase in our laboratories. This stage consisted of combining the ingredients in different proportions until the properties identified by Bathco were achieved.

What will this new material contribute to the bathroom sector?

This is a new formulation that, starting with traditional cement, results in a product that is lighter, more impervious to water, and one that enables a wide range of possible hues and finishes in the final product. In other words, it significantly improves on the properties of the cement washbasins currently on the market.

What are the characteristics of the resulting material?

The material developed results in an evolved washbasin, using an innovative material, with improvements in weight (40% lighter), impermeability (80% more resistant to water), and with a natural finish.

Bathco and the CTC are in discussions to develop a sustainable project. Could you fill us in on some of the details?

The development of this project is closely linked to studying the life cycle of the products. In other words, it’s a question of multiple research lines in this area to find out the point in the life cycle where the product adds value. Other aspects related to the project would be to identify and determine the critical environmental aspects, control and monitor these during the process or the reuse of the waste generated in the formulation and production of the materials.

What do sustainable projects do for companies?

Sustainable projects bring benefits in a variety of areas. In addition to helping sales and profitability, they also facilitate the inclusion of best practices in production and sales that generate social and environmental benefits. These projects are supported by economic factors, environmental factors, and social factors. Far from the perception that sustainable projects are associated with “non-competitive projects” that can “run up costs”, what they really do is reduce costs, expand uses for the product, improve the company’s public image, and raise quality levels. All of which benefits efficient management of companies.

Sustainable projects bring benefits in a variety of areas. In addition to helping sales and profitability, they also facilitate the inclusion of best practices in production and sales that generate social and environmental benefits. These projects are supported by economic factors, environmental factors, and social factors. Far from the perception that sustainable projects are associated with “non-competitive projects” that can “run up costs”, what they really do is reduce costs, expand uses for the product, improve the company’s public image, and raise quality levels. All of which benefits efficient management of companies.